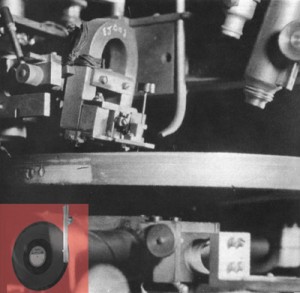

Edison electromagnetic record cutter (courtesy Edison National Historic Site)

Today’s vinyl records are made by much the same process as record disks made in the 1890s. First, an original recording was captured on a soft wax “master,” and then electroplating technology was used to make a hard metal stamper, from which multiple copies could be produced. There were numerous variations, of course.

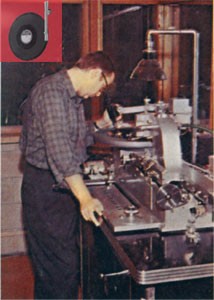

This series of photos (except for the first one) appears to have been taken in the late 1950s, and shows some of the operations that went into making commercial LP records at that time.

Photo from the 1950s showing a record “lathe” making a master disk. The operator is observing the groove through a microscope to ensure that a high quality recording is being made.

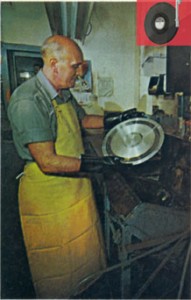

Silvering the master disk

The acetate is given a silver coating. By dipping it into a chemical bath through which a small electric current is flowing, dissolved silver is transferred to the surface of the disk, coating even the tiniest details in the groove.

Nickel and copper plating

The delicate plating on the master disk is built up by giving it additional plating baths to form nickel and copper layers. The plating is stripped away from the acetate, then used to make another heavy metal copy, called the mother. This mother copy is used to make one or more stampers, from which the vinyl discs will be pressed.

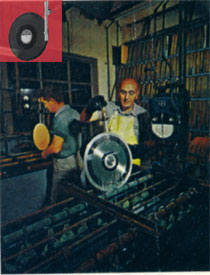

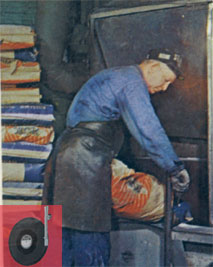

Elsewhere in the record pressing plant, a worker pours bags of powdered vinyl plastic into machinery that will heat it and prepare it to be made into records.

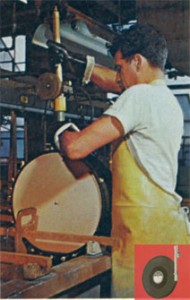

Pressing

A lump or “biscuit” of hot vinyl is placed into the stamper (shown here with its lid open). When the operator closes the stamper, it forces the molten vinyl into the grooves and forms a record. When the vinyl cools, the record is removed from the stamper and excess vinyl is trimmed from the edges.

Workers inserted the records into inner sleeves and outer jackets and put them into boxes for shipment.